You may have noticed a certain odour on the breeze over the last few years. We did too, and started taking action to investigate how we could take steps to help make sure our air is as beautiful as the view.

We know that sewage smell can be distressing. We are aware of the issue, committed to resolving it. We acknowledge that there remains a problem to solve, and we appreciate your patience as we continue to take steps to reduce odour impacts on our community.

Our Progress

Based on reports and public observations, council approved a capital project in 2023 for a study to identify the sources of odour and provide recommendations to mitigate them. The study recommended a phased solution.

We have completed Phases 1 and 2 and invested 2.6 million dollars in mitigation; however, we continue to receive reports of odours, indicating that additional assessment and work is required to address the issue.

Council approved a capital project for the first phase consisting of the installation of a chemical injection (dosing) system at the front of the plant to lower hydrogen sulphide (H2S) levels. This was completed in early 2024 at a cost of approximately $400,000. The dosing system did address the H2S levels, but did not address the broader odours generated from the plant.

Given that the first phase only partially solved the problem, in December 2024, Council approved moving forward with the second phase of the project at a projected cost of $2,200,000 (bringing the total cost of remedial efforts to $2,600,000).

The Phase 2 odour mitigation upgrade—featuring a photoionization unit at the solids handling building—was commissioned on June 26, 2025, and has been operating consistently since. We have observed a significant improvement in air quality within plant buildings. The air vented from the new unit has tested nearly odourless.

Despite this success, we have continued to receive odour complaints, particularly during a stretch of unseasonably rainy weather.

On Aug. 19, 2025, council directed administration to prepare a capital project for a Phase 3 Odour Upgrade at the Wastewater Treatment Plant, to be brought forward as part of the 2026 budget amendment process. In Phase 3, we would focus on the digesters, which are the two large holding tanks where anaerobic bacteria 'digest' the organic material present in the sludge as a food source.

On Sept. 16, 2025, council heard an update on next steps to address the issue. We've confirmed that the odour is coming from the digesters, which are two open air tanks. These tanks will need to be capped, along with a system installed to treat the emissions from the digesters.

On Oct. 7, 2025, council approved a $5M budget increase for phase 3 of the work. This phase of work addresses the digester tanks and will allow us to purchase a new capped holding tank and odour treatment system for that part of the process. The goal is to have this work complete by next summer.

In the meantime, we will continue to monitor site operations, weather patterns, and public feedback.

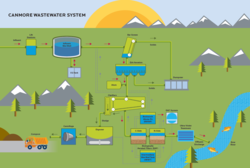

How does waste water treatment work?

Waste water treatment is a complex process. At a basic level, it involves removing contaminants and pollutants from the waste water that comes from our homes and businesses before returning the treated water to the environment.

EPCOR Water Services Inc., an operator of the Town’s water and wastewater treatment systems, is responsible for operating and maintaining our wastewater system.

Our Waste Water Treatment Plant has been operational since 1997. In our facilty, we screen and clarify solids during for primary treatment followed by biological aerated filtration for secondary and tertiary treatment. The treated wastewater passes through a UV disinfection unit prior to being discharged to the Bow River.

Some of the main processes that your waste water goes through to be cleaned so it is safe for people and the environment include:

Large objects like sticks and plastics are removed using bar screen.

A grit aeration chamber separates heavier inorganic materials like sand, gravel, and eggshells. Both the large objects and this grit get sent to the landfill.

- Wastewater flows into large tanks where heavier solids settle to the bottom as sludge, while lighter materials like grease and oil float to the surface and are skimmed off.

- The settled sludge and floating scum are removed from the tanks.

We put bacteria to work! By cycling air into the wastewater, we aerobic bacteria and other microorganisms to consume the organic pollutants as food.

Leftover material from the digestion process are spun out of the water and sent for composting!

Before releasing water in the Bow River, we treat it with ultra-violet rays to kill harmful bacteria and viruses.

We keep a close eye on our water quality. We perform regular analysis on different wastewater quality parameters to track overall water quality and evaluate toxicity.

As part of our work to reduce odours, we are also monitoring odour levels and other indicators.